Why Is End-to-end Milk Supply Chain Visibility Important?

Supply chain visibility is crucial for any business, especially perishable products like milk and dairy. Because of their shorter shelf life, keeping an eye on the products to avoid supply chain interruptions is important. Dairy ERP provides end-to-end management and monitoring of milk and dairy processing, from production and packing to dispatching and doorstep deliveries.

This blog explores why end-to-end milk supply chain visibility is crucial and how enterprise resource planning for dairy businesses helps you improve your supply chain operations.

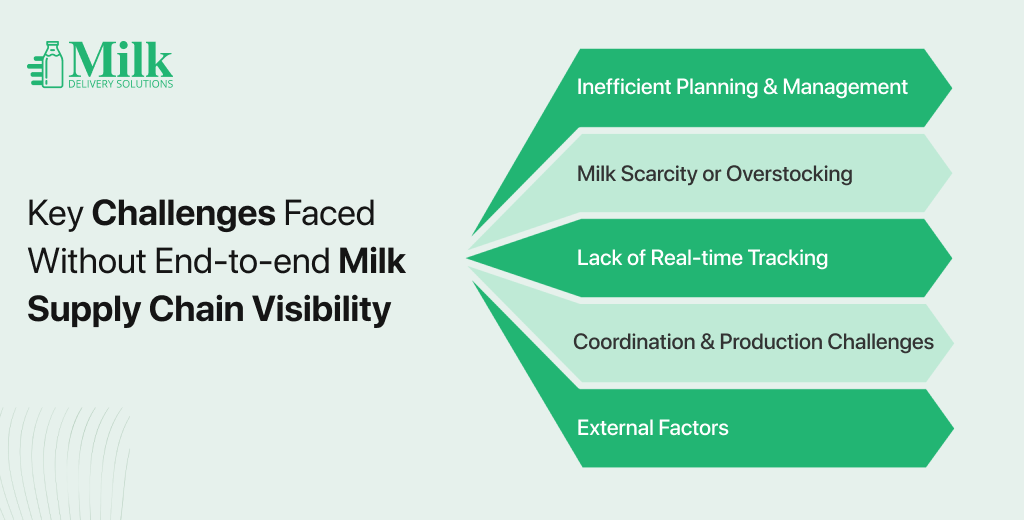

Key challenges faced without an end-to-end milk supply chain visibility

Considering the intricacies of the milk supply chain, the inability to view real-time operations can lead to disruptions and financial losses. Without the ability to monitor your operations, your company may be dealing with various issues. They can impact your business efficiency, profitability, and customer satisfaction. Some of these challenges are:

Inefficient planning and management

Without a complete view of the supply chain, planning can become guesswork. This makes forecasting demand, optimizing production schedules, or managing delivery routes challenging. Inefficient planning and management can lead to suboptimal resource allocation, underutilization or overstretching, and increased costs.

Inability to monitor the supply chain in real-time results in delayed decisions, making it difficult to react quickly to the changes in demand, supply, or unexpected disruptions in real-time. Inefficient planning can lead to higher operational costs due to waste, hastened shipping, or idle resources.

Milk scarcity or overstocking

They are caused by ineffective inventory management and the lack of real-time data. Milk scarcity occurs when the milk stock available is less than needed to satisfy consumer demand. Without visibility, stock shelves can go empty when demand is high or the supply chain is disrupted.

On the contrary, when the demand is sought to be high but is not, or production is not aligned with actual demand, excess milk can spoil. This leads to significant financial losses and waste. Efficient inventory management is crucial to ensure an optimal stock level to fulfill your customer demand timely manner without milk spoilage or missed sales opportunities.

Without real-time updates, physical inventory may not match records, leading to ordering errors or misallocation. Excess stock can increase holding costs, adding to expenses.

Lack of real-time tracking

This might not be a fundamental challenge; however, it can make monitoring milk difficult from farm to processing plant to retail. Milk requires strict temperature control, which makes proactively monitoring quality and temperature necessary to avoid potential milk spoilage. The complex nature of the milk supply chain makes prompt identification of bottlenecks. Without a real-time supply chain, it is impossible to do so, leading to production and delivery delays.

Delays in production and dispatching can result in delayed doorstep deliveries. Moreover, without real-time visibility, tracking deliveries and knowing the status of the shipments is impossible, impacting product freshness and customer dissatisfaction.

Coordination and production challenges

The milk supply chain involves various stakeholders, such as farmers, transporters, processors, distributors, and retailers. Without real-time shared visibility, each entity operates in a silo, leading to miscommunication, conflicting priorities, and inefficiencies in handsoffs.

Inconsistent milk supplies or unreliable transportation can lead to delays, impacting the overall production schedule. Poor coordination or collaboration makes it difficult to adapt to changing market conditions and expand operations.

External factors

While external factors are inherited challenges for any supply chain, a lack of real-time visibility increases their impact. Weather disruption, including floods, droughts, or extreme temperatures, can affect milk production at farms or disrupt transportation. Without visibility, it is hard to re-route or find alternative sources.

Animal diseases can significantly impact milk supply, and a lack of real-time visibility makes it difficult to assess the intensity of the problem and implement containment measures. Unforeseen transportation issues can cause delays, leading to product spoilage. Sudden market fluctuations, such as customer demand or milk price, make it hard to react without comprehensive data.

Regulations and compliance that make supply chain visibility essential

Regulations and compliance make supply chain visibility essential, especially for the sensitive and perishable milk industry. These bodies and their guidelines often mandate or strongly encourage practices that necessitate end-to-end visibility for safety, quality, and fair trends.

Codex Alimentarius Commission (CAC)

CAC is a joint FAO/WHO body that establishes international standards, guidelines, and codes of practice. While it is not a direct body, its standards are widely adopted by the national governments and serve as a benchmark for international food trade. Characteristics of the Codex Alimentarius Commission are:

- Emphasize traceability – Codex established international standards for traceability, recognizing it as a crucial tool for food safety, especially in managing recalls and identifying sources of contamination. “Principles for Traceability/Product Tracing as a Tool Within a Food Inspection and Certification System” of Codex addresses this.

- Good Hygiene Practices (GHP) and Hazard Analysis and Critical Control Points (HACCP) – Codex promotes GHP and HACCP principles that are fundamental to food safety.

Codex standards cover various aspects of milk and milk products, including hygienic practices, compositional standards, and methods of analysis and sampling. Sticking to these standards necessitates tracking and tracing milk from farm to farm to ensure compliance.

International Dairy Federation (IDF)

The IDF is a leading source of scientific and technical expertise for the global dairy sector. They define science-based standards, guidelines, and best practices for the industry. Characteristics of the International Dairy Federation are:

- Collaboration with ISO and Codex – IDF collaborates closely with ISO and Codex to provide technical input and expertise to shape international standards relevant to dairy.

- Safeguarding integrity and transparency – IDF ensures the safety and quality of milk and dairy products, promoting the adoption of robust traceability and visibility systems.

- Sustainable dairy practices – IDF advocates for sustainable dairy practices, which involve tracking environmental impact and ethical sourcing, pushing the need for real-time visibility.

International Organization for Standardization

ISO develops international standards for various management systems, which directly or indirectly drive real-time supply chain visibility. Characteristics of the International Organization for Standardization are:

- ISO 22000 (Food Safety Management Systems) – This is crucial for the food and dairy industry, specifying requirements for the food safety management system that covers all organizations in the food chain. Establishment and maintenance of traceability systems is a major requirement within ISO 22000. This makes identifying products and their components at all supply chain stages, mitigating risks, and efficiently recalling products.

- ISO 9001 (Quality Management Systems) – The ISO 9001 emphasizes process control, documentation, and customer satisfaction, leading organizations to implement better supply chain visibility to ensure consistent quality and meet customer expectations.

- ISO 22005 (Traceability in the Feed and Food Chain) – This specific standard provides general principles and basic requirements for the design and implementation of feed and food traceability systems. It addresses the need for clear, documented systems to track products and their ingredients.

National regulatory bodies

National regulatory bodies such as the FSSAI in India, the FDA in the USA, and the EFSA in Europe. These bodies have the authority to enact and enforce laws and regulations concerning food safety, quality, and labeling within the respective countries. These regulations mandate certain levels of traceability and visibility.

Conclusion

Operational challenges and mandatory regulations & compliance necessitate real-time milk supply chain visibility. They are crucial for dairy businesses to ensure effective supply chain disruption handling and high-quality milk and dairy products. If you are a business that is seeking a system for real-time operational visibility, schedule a meeting to discuss your requirements and see how we can help you.