What is Supply Chain Visibility in the Milk Business?

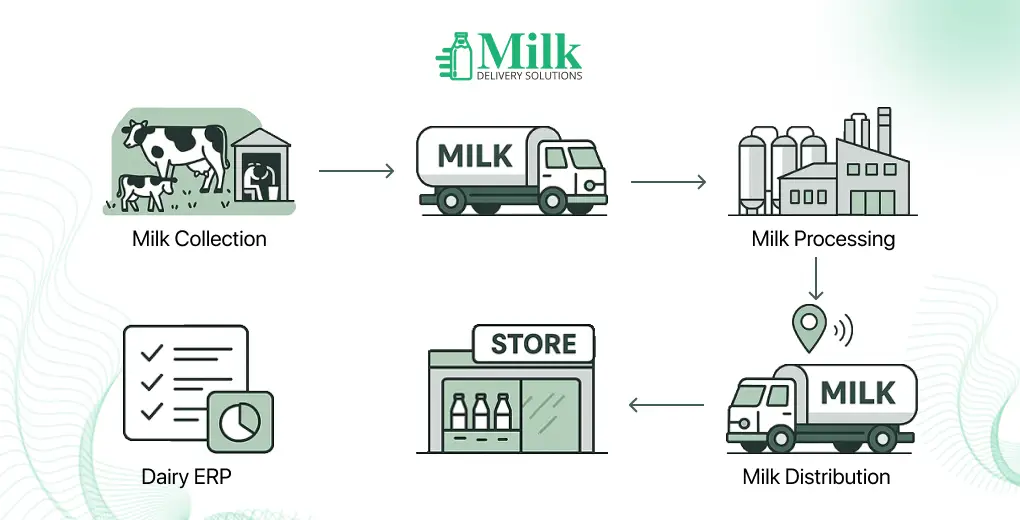

The milk supply chain is one of the intricate supply chains. Due to the perishable nature of milk and dairy products and increased regulatory compliance, end-to-end supply chain visibility is crucial. Modern supply chain visibility with dairy ERP empowers milk businesses to track milk and dairy products in real-time, analyze data from various points of contact, and make informed decisions.

Table of content

What is supply chain visibility in the dairy business?

Supply chain visibility in the dairy business refers to tracking and tracing every product in real-time and process in the milk supply chain, from milk collection to the final delivery of finished dairy products to the consumer. It provides a clear and complete picture of where your products are, their condition, and what is happening to them at a given moment. Reasons the milk supply chain needs real-time visibility:

- Perishability – Dairy products have a shorter shelf life, and delays or deviations in temperature can lead to spoilage and significant financial losses. Real-time supply chain visibility allows quick detection of issues that can impact freshness.

- Quality control – It’s critical for dairy businesses to uphold stringent regulatory standards. Visibility allows for proactive monitoring of quality parameters at every stage.

- Traceability – In case of product recall or quality issues, it is crucial to identify batches quickly and ensure consumer safety.

- Complex network – The dairy supply chain involves numerous stakeholders, including individual farmers, milk collection centres, chilling units, distributors, retailers, and consumers. It is challenging to achieve visibility across this diverse network.

Key challenges without supply chain visibility in the milk business

Operating a milk business without complete supply chain visibility is like shooting an arrow in the dark, resulting in expensive mistakes. Here are the hurdles faced by the milk business lacking supply chain visibility:

Data silos and fragmentation

Without integrated or centralized data, comparing milk collection with processing capacity, optimizing production schedules, or accurately tracking batches from farm to consumer is difficult. This can lead to overproduction of some products, underproduction of others, and difficulty identifying quality issues.

Lack of real-time tracking

This increases the chances of spoilage of perishable milk and dairy products, missed deadlines, inefficient route planning, and an inability to conduct timely recalls in case of contamination. It can hamper your product’s safety and freshness.

Inefficient collaboration

Inability to communicate clearly with your suppliers can lead to minimal milk procurement schedules, delays in processing due to unexpected milk volumes, disputes over quality, and a bad customer experience. Coordinating efforts to meet customer demand or address quality concerns immediately is difficult.

External factors (geopolitical or natural disasters)

A natural disaster like a sudden flood can cut off milk collection routes, leading to milk dumping and financial losses for farmers and the dairy business. A heatwave can impact milk quality and volume. Without visibility, it is difficult to identify affected regions, reroute transport, activate unpredictable plans, or communicate effectively with affected stakeholders, leading to significant product loss, revenue hits, and damage to the farmer relationships.

Importance of supply chain visibility

Several regulatory bodies enforce standards and guidelines, making real-time, end-to-end visibility crucial for compliance and avoiding penalties. ERP plays an important role in dairy industry businesses complying with these stringent regulations. Some of these regulatory bodies are:

Codex Alimentarius Commission (CAC)

It is an international food standards body established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) in 1963. The Codex Alimentarius Commission (CAC) has strict standards concerning milk and milk products that cover aspects such as hygiene, composition, labeling, additives, and contaminants. This requires detailed record-keeping and traceability to prove compliance with hygiene practices, ingredient specifications, and contaminant limits throughout the supply chain.

International Dairy Federation (IDF)

IDF is a popular source of scientific and technical expertise for the dairy sector. It collaborates closely with Codex and ISO. It covers milk quality, processing technologies, animal health, and environmental sustainability. These aspects are directly connected with the need for visibility.

International Organization for Standardization (ISO)

ISO is an independent, non-governmental organization that develops and publishes international standards across various industries, including food safety. Standards like ISO 22000 (Food Safety Management Systems) and ISO 9001 (Quality Management Systems) provide frameworks for dairy businesses to ensure food safety and quality. ISO standards focus on a systematic approach to management, including traceability, risk management, and continuous improvement.

National regulatory bodies

The national regulatory bodies include FSSAI in India, FDA in the USA, and EFSA in the EU. They set comprehensive standards for milk and milk products, including everything from raw items to processing, packaging, labeling, and distribution. They enforce strict quality, limit parameters, and require proper hygiene and manufacturing practices. These compliances necessitate robust internal control and comprehensive documentation throughout the supply chain.

Characteristics of a functional milk supply chain

A functional milk supply chain is a tangible and strategic advantage for milk businesses aiming to overcome market complexities.

Seamless flow of data

Data flows seamlessly from end to end in a transparent supply chain. The data from milk collection points, processing units, warehousing, and distribution is collected and shared in a unified manner.

Real-time tracking & monitoring

It includes GPS tracking of the milk tankers’ routes, real-time updates on milk volume collected from each farmer, and instantaneous quality checks at collection points. Using IoT sensors in refrigerated vehicles to monitor temperature and humidity. Proactively monitoring temperatures in chilling tanks and processing units, and real-time updates on inventory levels and expiration dates in cold storage.

Proactive issue resolution

Analyzing historical data and current trends to predict demand for optimizing production planning and preventing stockouts and oversupply. Predicting possible malfunctions and scheduling maintenance before failure happens is made possible by equipment data. Identify potential disruptions and have strong plans in place. The system triggers automated notifications when a deviation occurs.

Informed decision-making

Business intelligence dashboards, reporting tools, and analytics platforms transform raw data into actionable insights, providing information needed to make strategic and tactical choices.

How to achieve milk supply chain visibility?

The milk supply chain is very complex and requires a multi-faceted approach to achieve complete and clear milk supply chain visibility. Here are the tools that can help you achieve real-time supply chain visibility:

ERP

Enterprise resource planning is a comprehensive platform with multiple ERP modules to manage, track, and trace your business operations. The system provides a centralized data repository that stores all the data related to milk collection, inventory, sales, finance, and logistics in one place. The system connects various operational modules, ensuring seamless data flow. It also allows you to track milk and dairy product batches from the farmer’s gate to the consumer’s fridge.

IoT sensors

These Internet of Things sensors are used for fill-level monitoring, asset performance, and temperature and humidity monitoring. It collects real-time environmental and operational data from physical assets throughout the supply chain.

GPS tracking

It includes tracking the real-time location of the milk tankers, delivery trucks, and even field collection vehicles at any given moment. GPS tracking helps plan efficient routes and ensures drivers stick to them. It also provides accurate ETAs for milk collectors and product deliveries for better planning of chilling centers, processing plants, and distribution hubs.

Mobile apps

Mobile apps facilitate data capturing and information access for field personnel and suppliers, especially in the distribution networks. Milk collection agents can record milk quantity, fat/SNF content, and farmer details digitally at the collection points. Farmers can view their milk collection history and payments. The delivery driver milk delivery app enables drivers to receive routes and updated delivery statuses, capture digital proof of delivery, and report issues to go.

Lab technicians use quality control apps to record quality test results at various stages. Sales/field agent app allows the sales team to place orders, check inventory, and monitor retail shelf stock. You can also offer a milk delivery app to customers to place their subscription or one-time orders. This order data is automatically updated on the ERP system.

Barcode & RFID technology

It automates identifying and tracking individual items, cartons, pallets, and batches. Barcodes and RFID tags on raw materials, work-in-progress, and finished goods enable automated scanning at receiving, during production, and dispatch to ensure accurate inventory counts in real-time.

Data analytics & business intelligence

Several technologies can transform vast raw data into actionable insights. Reports, trend analysis, predictive analysis, root cause analysis, and performance dashboards can all be used to gain real-time visibility.

How does dairy ERP provide real-time milk supply chain visibility?

Dairy ERP is a one-stop solution that automates and streamlines your entire business, offering end-to-end, real-time operational visibility into the processes. Ways dairy ERP provides milk supply chain visibility are:

Integrated data

ERP is a cloud-based platform that stores all your business data in one place. It standardizes the data, ensuring data consistency throughout the supply chain. This integrated data helps understand the milk supply chain end-to-end, from procurement to fulfilment, fostering better planning, decision-making, and collaboration.

Real-time tracking and monitoring

ERP systems centralize data, automate workflows, generate alerts and notifications, and can be integrated with multiple systems. This allows milk businesses to track and monitor milk and other products and resources throughout the supply chain. This empowers you with continuous management, improved decision-making, and faster response to disruptions.

Data analytics & reporting

Dairy ERP consolidates and processes data, including sales, inventory, production, and logistical data. It empowers businesses to identify supply chain bottlenecks or disruptions and address them promptly.

Collaboration & communication

ERP provides a centralized platform for sharing information, tracking inventory, and managing the flow of milk and other products, leading to efficient and responsive supply chains. Data updated from one department is accessible to different departments, enabling smooth collaboration and communication.

Automation and efficiency

The system provides real-time visibility into production, logistics, and inventory, integrating multiple business operations. This empowers businesses to make data-driven decisions and streamline operations. This real-time visibility allows better planning, reduces costs, and improves collaboration across the supply chain.

Supplier performance management

The system allows you to track and analyze supplier performance, identify potential issues, and optimize the supply chain. Dairy ERP systems provide a centralized view of the supply chain, enabling real-time monitoring and data-driven decision-making.

Customer relationship management

ERP systems provide a consolidated view of your customers and enable you to manage and track interactions. The system can analyze customer preferences, allowing you to offer a personalized experience. Based on consumer information and preferences, you can coordinate your marketing initiatives.

Cost saving and increased efficiency

ERP system provides real-time insights into every aspect of the milk supply chain, enabling you to spot supply chain interruptions and take appropriate action. This allows you to save on rework and product spoilage costs.

Enhanced supply chain resilience

ERP systems allow you to proactively manage risks, optimize operations, and effectively adapt to supply chain disruptions. Improving milk supply chain visibility lets you make faster, informed decisions and more efficient resource allocation, leading to a robust and responsive supply chain.

Data-driven decision-making

ERP gives dairy companies real-time visibility and analytics for better production, logistics, and inventory decisions. This improves operational efficiency and reduces waste, saving money.

Benefits of real-time end-to-end milk supply chain visibility

The enterprise resource planning system provides real-time end-to-end supply chain visibility, aiming to improve operational efficiency, customer satisfaction, and sustainability. The advantages of end-to-end supply chain visibility are:

Improved risk management & reduced disruptions

Real-time visibility enables proactive issue identification, quick response to supply chain disruptions, enhanced traceability, and resilience against sudden events. This improves your risk management strategies and reduces milk supply chain disruptions.

Enhanced efficiency and reduced costs

The system can help you enhance operational efficiency and reduce costs. It optimizes routes and logistics, reducing fuel consumption and transportation costs. Monitoring conditions like temperature and humidity can prevent milk spoilage, leading to less product spoilage and associated financial losses. Automation streamlines data collection and reporting, reducing manual errors and freeing employees to work on more strategic tasks.

Better inventory management and minimized stockouts

ERP has a predictive analytical model that helps you forecast demand accurately, optimize inventory levels, prevent stockouts, and reduce lead times. Efficient inventory management can lower stock holding costs and ensure optimal stock levels to fulfill customer demands on time.

Increased customer satisfaction

Implementing ERP for dairy businesses ensures milk and dairy product freshness and quality. Minimizing supply chain disruptions and efficient logistics lead to more consistent and on-time deliveries, building customer trust, and improving satisfaction rates. The system enables businesses to better respond to customer inquiries.

Improved sustainability and compliance

The system provides 360-degree milk supply chain visibility, reduces carbon footprints, ensures ethical milk sourcing verification, adheres to strict regulations, and enhances corporate social responsibility. Improved sustainability and compliance provide opportunities to establish your business as a “BRAND”.

Supply chain visibility data: measuring KPIs

The dairy supply chain is complex, and handling its bottlenecks efficiently requires implementing robust technology that provides real-time end-to-end visibility. Complete supply chain visibility and operational control are crucial for businesses to survive and thrive in the competitive landscape.

Milk Delivery Solutions provides a dairy ERP that automates all your business operations and offers end-to-end milk supply chain visibility to spot issues and handle them promptly. Schedule a meeting to discuss your dairy business requirements and see how our ERP system can help your business.